HOSE IS SELECTED?

The selection and installation of a flexible hose depends on the pressure of the circuit to connect, working cycles, continuous or water hammer, the inner diameter of the hose and type of the fluid to use.

According to the EN, UNI ISO, DIN and SAE, the recommended working pressure ratio is 1:4.

The MAIBERFLEX hoses have normally good resistance to the ozone action, solar radiation, other atmospheric agents, water and oil. For any particular use, contact with our technical department.

In installations wherepressure cycles rise suddenly is necessary to select a hose that can increase the safety factor. On the other hand, a MINIMUM value of the safety factor is enough when water hammer is soft or does not exist.

The specific working temperature for each hose type is the maximum temperature for the fluid that goes through the hose (higher temperatures can be supported by small period of time). The constant operation at maximum temperature reduces the hose life.

EXPANSION

Heat sources or excess cold nearby the flexible hose may damage the outer cover and the reinforcement negatively affecting the hose life.

FLUIDS

The hose selection for high pressure gaseous applications must be done carefully. Moreover, for chemical installations, but in this case, could have positive effects to prevent any accidental break.It is recommended to increase the safety factor.

THE HOSE?

When the flexible hose is working at the operating pressure, its length can vary from +2% to -4%. Be careful and prevent that the length of the flexible hose is the same than the distance to fit when it is working under traction. Do not bend the hose with a smaller radius than the specified in the characteristic table, this way high fatigue and hose inner diameter reduction are avoid. If the hose is excessively bended, can make that the hose reinforcement does not work uniformly, reducing the properties. Each installation must be done with the correct fittings in order to avoid very big or small curves achieving easy assembly maintenance. If the hose is located in a position that could be in contact with metallic parts or friction, protect it with a plastic or metallic protection.

The MAIBERFLEX flexible hoses must not be exposed to direct heat sources. In these cases, it is necessary to protect them with Firesafe.

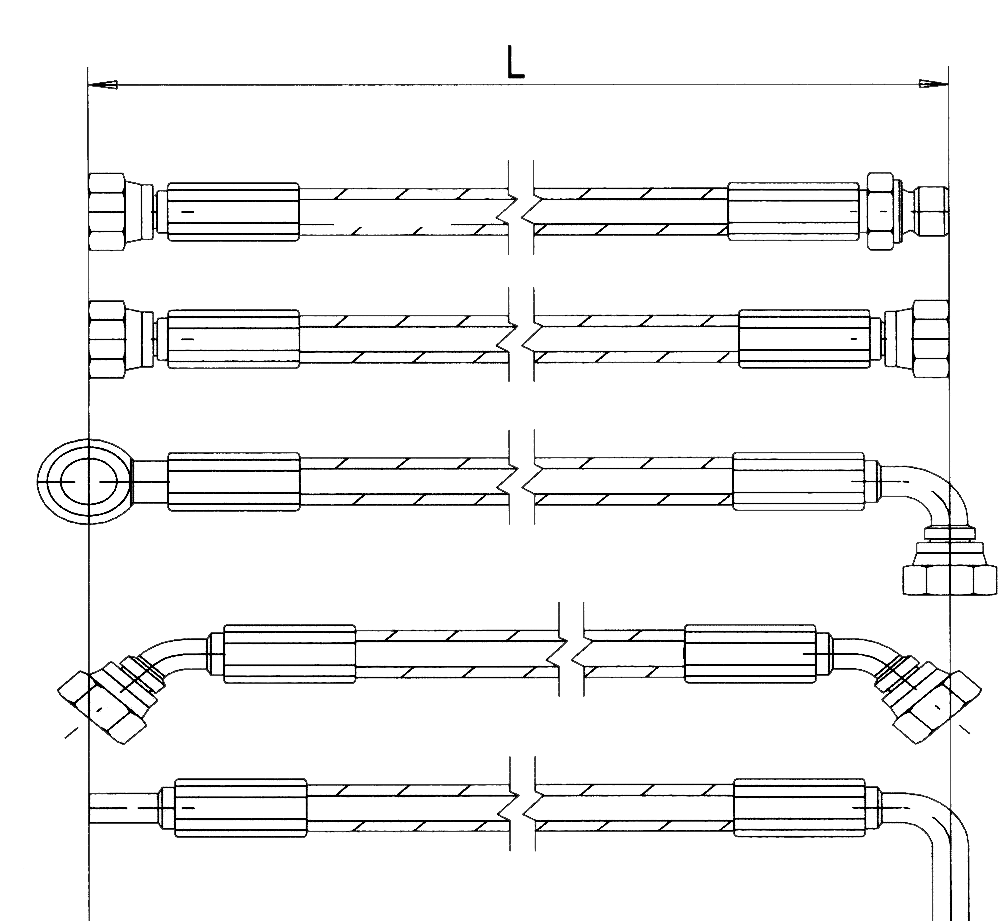

In the next picture, information about the correct way to measure the hose is shown. According to DIN y SAE standards, the hose length can vary from +2% excess to -4% defect depending on the working pressure. That is why, is recommended to consider the final length evolution of the hose. Moreover, a +/-3% tolerance must be considered from the final length.

In case of 2 pointed arch hoses or elbows, the relative angle between fittings must be defined (+/-3% tolerance). The most used positions and angles are shown, in the next picture identified with four letters (A-B-C-D)

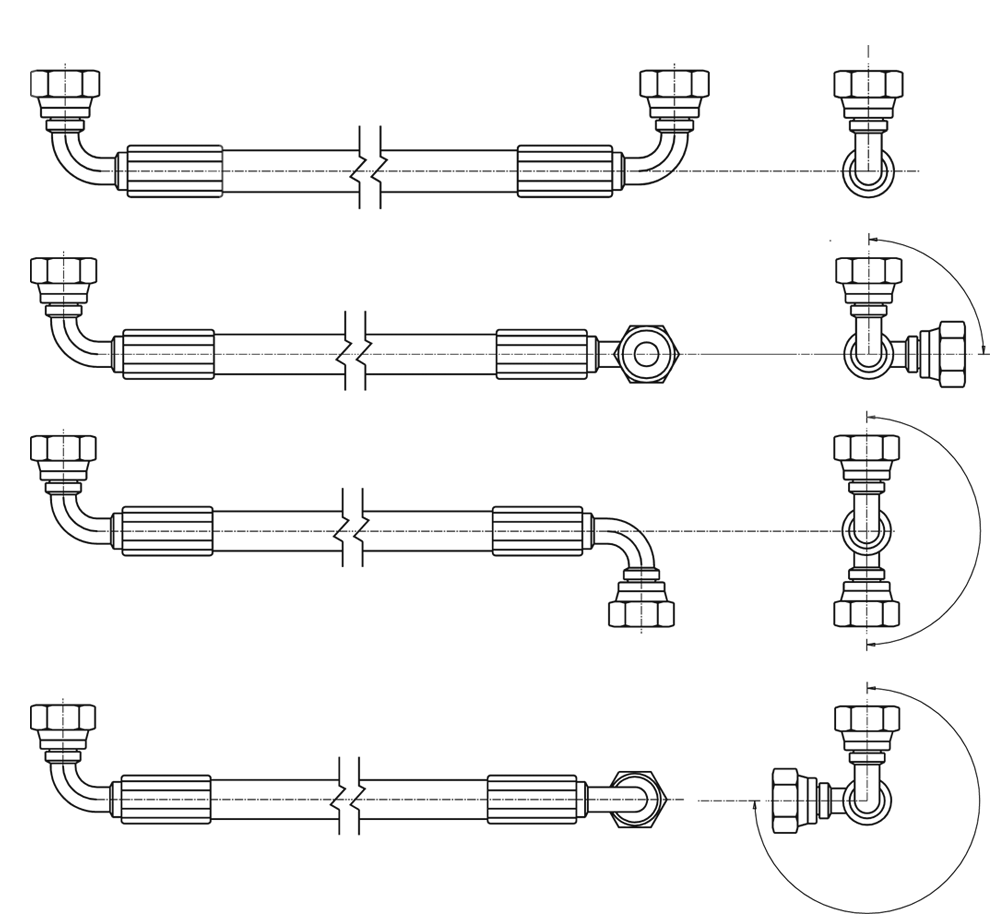

With the objective to achieve the best performance, consider the next recommendations: the flexible hoses must work under the theoretical pressure and bend radius limits according the specific data tables.The hose must not support torsion and the hose length must be six times the pipe diameter at least, measure from the fittings. The fitting type must reduce the number of the curves to the mMINIMUM. In the next graphics, correct and incorrect couplings are shown.

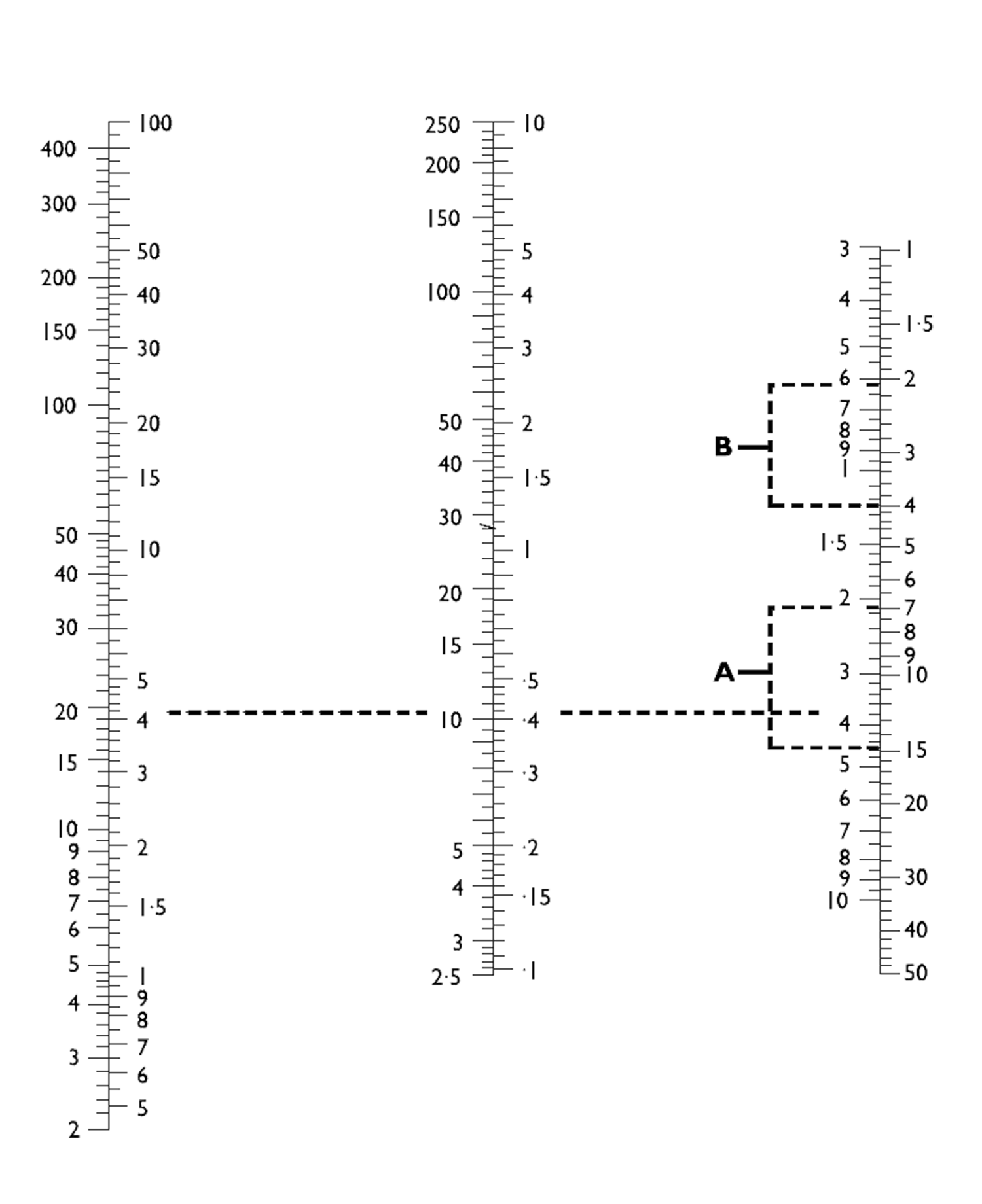

A: Speed range recommended for pressure lines.

B: Speed range recommended for return lines.

√ EXCELENT X UNSATISFACTORY √* EXCELENT, BUT

|

NYL6: Nylon 6 PEL: Elastomer Polyester NYL11: Nylon 11 PIFE: Teflon |

1SN 2SN 4SP 4SH R12 R13 |

NYL6 |

PEL |

NYL11 |

PTFE |

|

OIL ASTM NO.1 |

√ |

√ |

√ |

||

|

OIL ASTM NO.2 |

√ |

√ |

√ |

||

|

HYDRAULIC OIL |

√ |

√ |

√ |

√ |

√ |

|

BUTILE ACETATE |

X |

√ |

√ |

√ |

√ |

|

ACETILENE |

√ |

√ |

√ |

√ |

|

|

ACETONE |

X |

X |

X |

X |

√ |

|

HYDROCLORIDRIC ACID |

√ |

√ |

√ |

√ |

√ |

|

WATER |

√* |

√* |

√* |

√ * |

√ |

|

AIR |

√ |

||||

|

AIR (DRY) |

√ |

√* |

√* |

√ * |

√ |

|

COMPRESSED AIRE |

√ |

||||

|

ALCOHOL (METHANE ETHANOL) |

X |

X |

X |

√ |

|

|

LIQUID AMMONIA |

√ |

√ |

√ |

√ |

|

|

BENZENE |

√* |

√* |

√ * |

√ |

|

|

BUTANE |

|||||

|

CARBONATE |

√ |

√ |

√ |

√ |

|

|

BEER |

X |

||||

|

CHLOROFORM |

√ |

√ * |

√* |

√ |

|

|

CARBON DIOXIDE (DRY) |

|||||

|

ETHER |

X |

√ |

√ |

||

|

BRAKE FLUID |

√ |

||||

|

FREON 12 |

√ |

||||

|

FUEL-OIL |

√ |

√ |

|||

|

NATURAL GAS |

X |

√* |

X |

√ * |

√ |

|

GASOLINE |

√ |

√ |

√ |

√ |

√ |

|

GLICERINE |

√ |

√* |

√ * |

√ |

|

|

MINERAL FATS |

√ |

√ |

√ |

√ |

√ |

|

VEGETABLE FATS |

√ |

||||

|

GASEOUS HIDROGEN |

√ |

√ |

√ |

√ |

√ |

|

AMMONIUM HYDROXIDE 25% |

√ |

√ |

√ |

√ |

|

|

KEROSENE |

√* |

√ * |

√ |

||

|

OXIGEN |

√ |

X |

X |

√ |

|

|

LIQUID PROPANE |

|||||

|

ALKALINE SOLUTIONS 50% |

√ |

√* |

√ * |

√ |

|

|

TOLUENE |

√ |

√ |

√ * |

√ |

|

|

SATURED STREAM |

X |

√ |

√ |

√ |

√ |

DO YOU NEED MORE INFORMATION? DO YOU WANT A BUDGET?

> CONTACT US<

Subscribe to our Newsletter

CONTACT

MAIBERFLEX

Calle Lisboa, 33

28813 Torres de la Alameda

Madrid (SPAIN)

T 918 868 402

E info@maiberflex.com

W www.maiberflex.com

BUDGET

How can we help you? If you need valuation of any of our products, send us the form.

CATALOGUE

View or download our catalog of the full range of Medium-High Pressure Hydraulic Hoses.